Woven wire mesh is one of the most adaptable materials in the world, facilitating a wide range of operations in a variety of sectors. Woven wire mesh has an impact on our daily lives in a variety of ways, from enhancing the architecture of a structure with a dynamic aspect to filtering out harmful particles.

However, understanding the concepts and applications of woven wire mesh can be difficult at first. This begs the question: what exactly is woven wire mesh?

We appreciate that woven wire mesh can seem underwhelming at times, but throughout the years, we have seen mesh offer actual outcomes that have altered our customers' operations.

For that purpose, we wrote this article to shed light on:

• What is woven wire mesh and how is it made?

• What is the price of woven wire mesh?

• Wire mesh form factors

• Applications for woven wire mesh

What is woven wire mesh and how is it made?

.jpg)

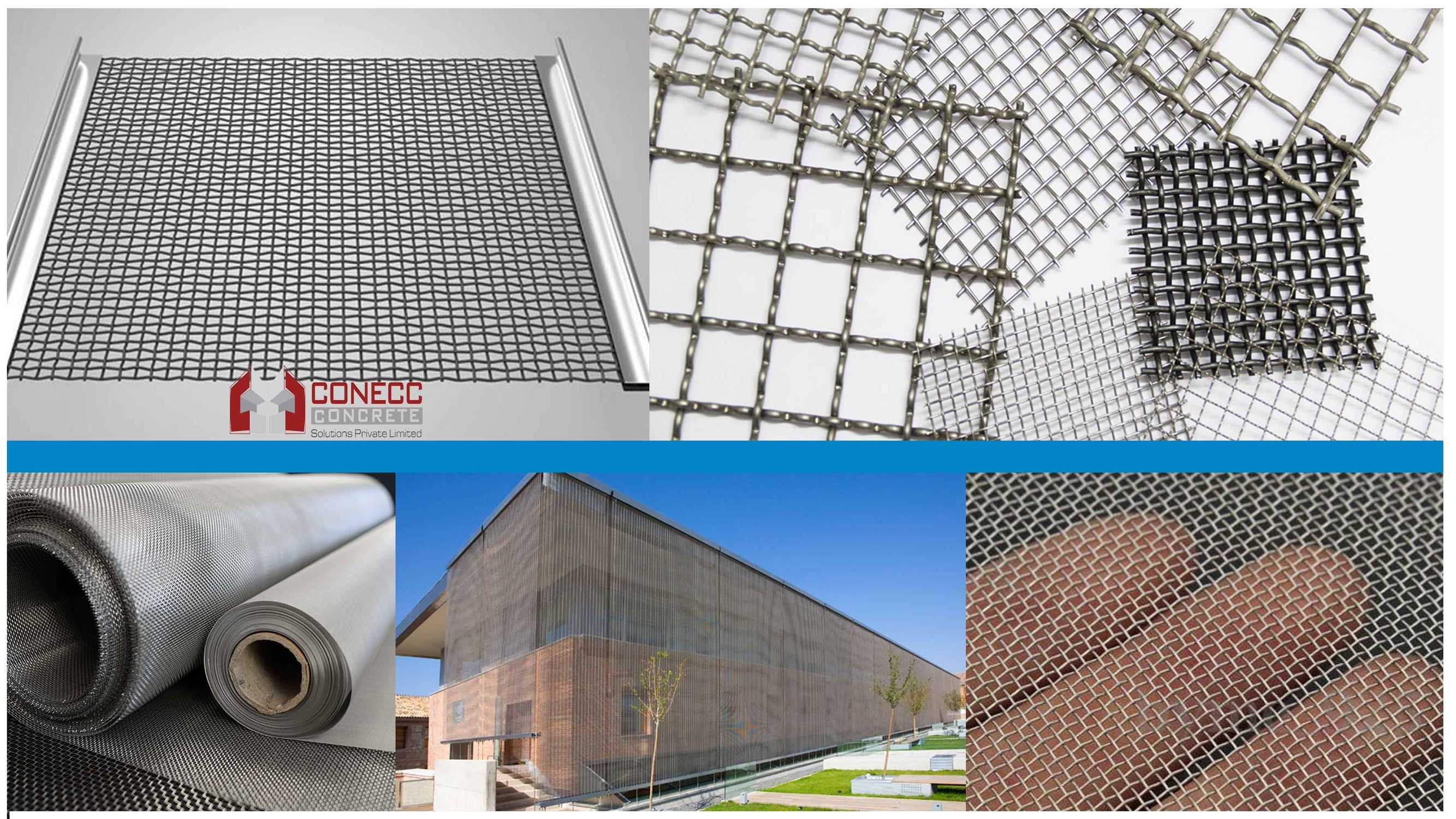

Woven wire mesh, also known as woven metal mesh and wire cloth, are rolls, sheets, or components made of interlocking metallic wires that are woven into a specified weave pattern. The number of individual wires used to build the mesh, as well as the weave pattern, wire diameter, aperture size, micron rating, breadth, and length, are all predetermined.

Woven wire mesh is created by weaving metallic wires on a specialized weaving loom. Looms are normally set up to weave 48", 60", or 72" mesh rolls; however, 98" and wider mesh rolls have recently been available. The weaving loom now works to connect each individual wire utilizing tension at each cross-section to keep the mesh intact, employing a weaving process similar to that used to make clothing. Currently, available technology allows for aperture diameters ranging from 5 microns to 4".

What is the price of woven wire mesh?

The elements that determine the cost of wire mesh are the same whether you are using sieve cloth, industrial mesh, architectural mesh, or filter mesh. Size, shape, mesh specification, number, alloy, and layer layout are all included (fabricated parts). Any additional needs, such as DFARS compliance and value-added services, will be factored into the mesh's overall cost.

Wire mesh form factors?

All woven wire mesh products are woven in the same way. However, wire mesh is available in three different forms, each with its own set of advantages.

There are three types of mesh: square mesh, filter mesh, and architectural mesh:-

Square Mesh

Woven wire square mesh is a type of wire mesh that is made out of weft and warp wire with similar wire diameters. Depending on your requirements, it can be woven in plain weave, inter-crimped weave, or pre-crimped weave standards. Square mesh is commonly offered in wire mesh rolls or cut into pieces.

Filter Mesh

Metal mesh filters, commonly known as stainless steel filter mesh, are types of wire mesh in which a network of metallic wires is braided to generate narrow and rigid pore holes. Filter mesh is commonly used to remove impurities from a given substance or to extract specific particles in order to make a filter cake.

When it comes to supply, filter mesh is available in rolls or cut-to-size pieces, similar to square mesh. Filter mesh can also be made to a specified size and form to meet your filter system.

Architectural Mesh

The architectural mesh also called metal mesh fabric, is a high-tensile mesh variation that is employed as a design element during the architectural design process. To be as environmentally friendly as possible, the mesh is often made of 316-stainless steel that has been up to 80 percent recycled.

While the mesh is robust enough to offer a safer environment inside parking garages, there is also a feeling of flexibility once tensioned. This enables it to be used on practically any structure, irrespective of whether the structure's design specifications are regular or irregular.

Applications for woven wire mesh?

Sieve Cloth

Sieve cloth is woven wire mesh that is specifically designed to be used in test sieves. The fact that sieve cloth is woven to a predetermined nominal opening with a particular wire diameter distinguishes it from other mesh types. More importantly, it is weaved in accordance with ASTM E11 and ISO 3310-1 specification. It is typically used to test sieve construction, but it can also be used for large-scale screening activities.

Industrial Mesh

Industrial wire mesh refers to the use of square mesh or filter mesh on a big scale. In other words, industrial mesh is acquired in rolls or vast amounts of cut-to-size pieces.

In terms of applications, industrial mesh is ideal for industries that want to reap the benefits of wire mesh while managing any special fabrication in-house. This covers the automotive, medicinal, and filtration industries.

Screen Printing

When the proper mesh holes are used, stainless steel wire mesh can provide significant advantages to any screen printing process. In comparison to alternative materials, such as nylon mesh, wire mesh provides improved tensioning, durability, ink spread, and cost savings.

Fabricated Parts

As previously noted, wire mesh can be manufactured in a variety of sizes and shapes. A value-added service must be done to produce the desired form for a wire mesh part to be deemed manufactured.

While the applications for wire mesh are nearly unlimited, the most typical forms are cut-to-size components, deep-drawn parts, edged solutions, pressed products, and cylindrical filter cartridges.

Best Manufacturer of woven wire mesh in Karnataka Conecc. We provide wire mesh products according to different shapes, sizes, and designs according to the desired need of the customers.

Our Products - AAC Blocks, Precast Walls

Read More Blogs Like These: Blog, AAC, CONECC AAC BLOCKS